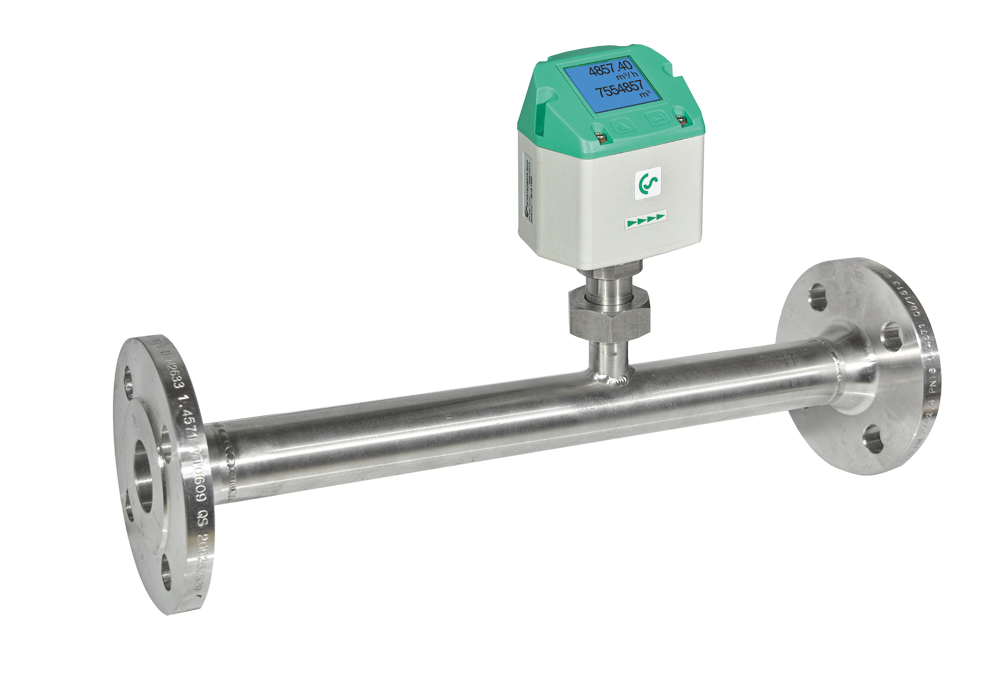

Air Flowmeters for Measurement and Control in Manufacturing Facilities

In the realm of industrial processes, precision and efficiency are paramount, and nowhere is this more evident than in manufacturing facilities where air flow plays a pivotal role. Air flowmeters have emerged as indispensable instruments for the measurement and control of airflow within these environments, facilitating optimization of various manufacturing processes. These devices serve a dual purpose, providing accurate measurements of air velocity and volume while enabling real-time adjustments for enhanced control. Air flowmeters are crucial for maintaining optimal conditions in manufacturing facilities. These devices play a crucial role in ensuring the proper functioning of ventilation systems, regulating air quality, and mitigating the risks associated with airborne contaminants. By precisely measuring air velocity and volume, these flowmeters enable manufacturers to implement targeted interventions, ensuring that production areas remain compliant with industry standards for air quality and safety. This level of control is particularly vital in sectors such as pharmaceuticals, electronics, and food processing, where stringent environmental conditions are non-negotiable.

Moreover, air flowmeters contribute significantly to the overall efficiency of industrial processes. By providing accurate measurements, these devices empower manufacturers to identify and address inefficiencies in the air distribution system. Fine-tuning airflow in heating, ventilation, and air conditioning HVAC systems, for instance, allows for the optimization of energy consumption, reducing operational costs and minimizing environmental impact. This level of control not only aligns with sustainability goals but also enhances the overall competitiveness of manufacturing operations. The integration of air flowmeters into manufacturing processes also facilitates proactive maintenance strategies. With real-time data on air velocity and volume, operators can identify deviations from optimal conditions, signaling potential issues such as clogged filters or malfunctioning equipment. This early detection enables timely preventive maintenance, reducing downtime and preventing costly disruptions to production schedules.

In addition to their monitoring and control capabilities, modern air flowmeters often come equipped with advanced features such as wireless connectivity and data analytics wt farley. This connectivity allows for remote monitoring and control, enabling manufacturers to oversee multiple facilities from a centralized location. Furthermore, the integration of data analytics enables the extraction of valuable insights, supporting informed decision-making and continuous process improvement. In conclusion, air flowmeters have become indispensable tools for optimizing industrial processes in manufacturing facilities. Their ability to provide accurate measurements of air velocity and volume, coupled with real-time control capabilities, ensures the maintenance of optimal conditions for production. By facilitating efficiency improvements, supporting proactive maintenance, and incorporating advanced features, these devices contribute significantly to the overall productivity, sustainability, and competitiveness of modern manufacturing operations.